Quick sharing

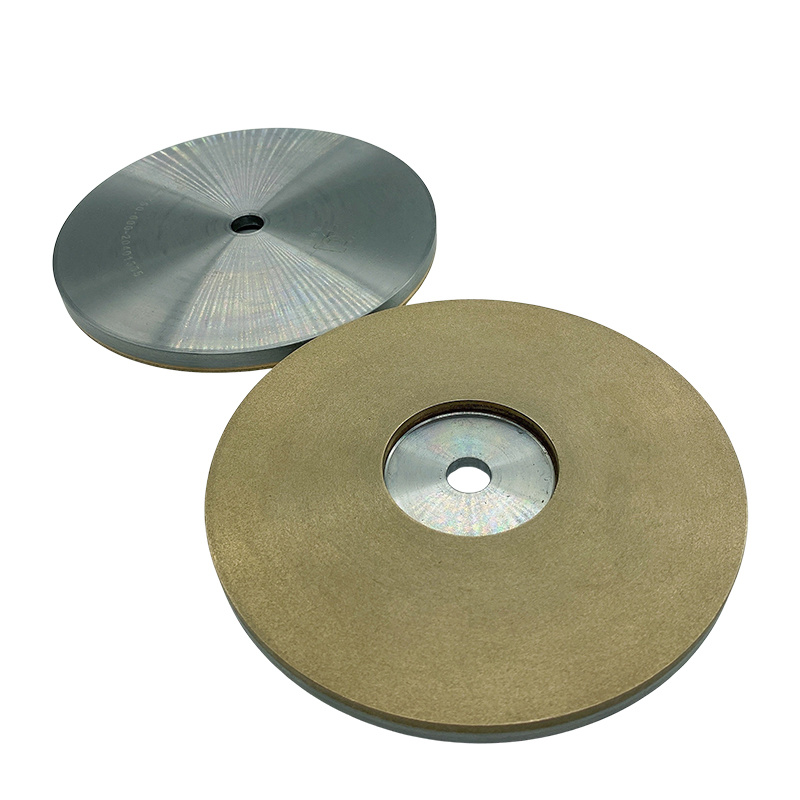

Sintered grinding metal wheel diamond polishing disc wheel for glass stone polishing

Are you still hesitating? You can contact our product experts first!

- Product Description

-

Feature:

1. Good Polishing result and high efficiency

2. Long lifespan and stable performance

3. Easy and fast polishing, no edge broken.

4. Highly cost effective and premium quality

5. Using high quality material and Enough Diamond

With special steel plate as the substrate, high-quality diamond particles are inlaid on the substrate plane by scientific sintering method, and finely grounding various glass, crystal, quartz, ceramics, stones and other workpieces.

It is characterized by fast grinding speed, no edge collapse of workpiece, good control of grinding surface size, and various particle sizes can be selected according to different requirements of processing workpiece. It can be processed according to customer's technical requirements or drawings.

Product Name

Sintered Diamond Lapping Disc

Application

Glass, Stone, Gems, Agate, Jewelry polishing

Customized support

OEM, ODM, OBM

Size

150x12.7x9mm (3mm diamond layer)

150x12.7x10mm (4mm diamond layer)

200x12.7x14mm (5mm diamond layer)

300x12.7x15mm (6mm diamond layer)

450x12.7x15mm (5mm diamond layer)

Bore

12.7mm, 25.4mm, or without bore

Grit

46#-1200#

Shape

Round Flat wheel

Thickness

5-25mm

Package

2pcs/box

Product packaging

• If the quantity of order is not very big,we could send them to you by express delivery,such as TNT,DHL,UPS OR EMS etc.

• If the quantity of order is not very big,we could send them to you by express delivery,such as TNT,DHL,UPS OR EMS etc.

• If order is big,we willadvise you use Air Shipping or Sea Shipping through your nominated forwarder agent.Our long-term cooperated agent also available.

• Freight collect if bulk shipment..

Application

Sintered grinding metal wheel diamond polishing disc wheel for glass stone polishing

INQUIRY

Attention: Please leave your email address, and our professionals will contact you as soon as possible!

Recommended products